Read more

Read less

Read more

Read less

Read more

Read less

Your Future Lab Perspective

»Making polymer products and components substantially and measurably more sustainable according to the »Reduce, Reuse, Recycle« concept without compromising product quality and performance«

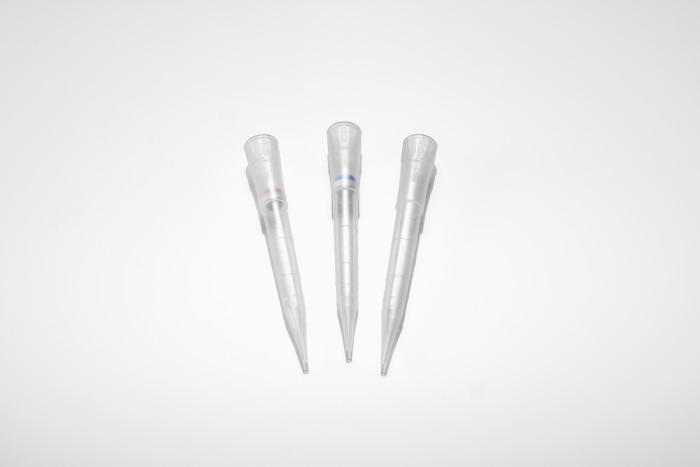

Since oil-based plastic consumable have replaced glass consumables, they have become irreplaceable in laboratories around the world, providing quality standards needed in increasingly demanding research. This is the growing challenge in respect to sustainability. Thus, Eppendorf not only focuses on the development of new products but also on new, more environmentally friendly manufacturing materials. For the first time, we are in a position to offer, in addition to the generation of Eppendorf Tubes® BioBased und epT.I.P.S.® BioBased pipette tips, the first polycarbonate twin.tec® PCR Plates BioBased for the frame, as well as polypropylene for the wells, which are made of certified plastic based on renewable reused raw materials.

Special product highlights

- The Eppendorf Production Center in Oldenburg / Germany is ISCC PLUS (International Sustainability & Carbon Certification) certified.

- ACT labeled (Accountability, Consistency, Transparency) – Environmental Impact Factor Certification conducted by My Green Lab®

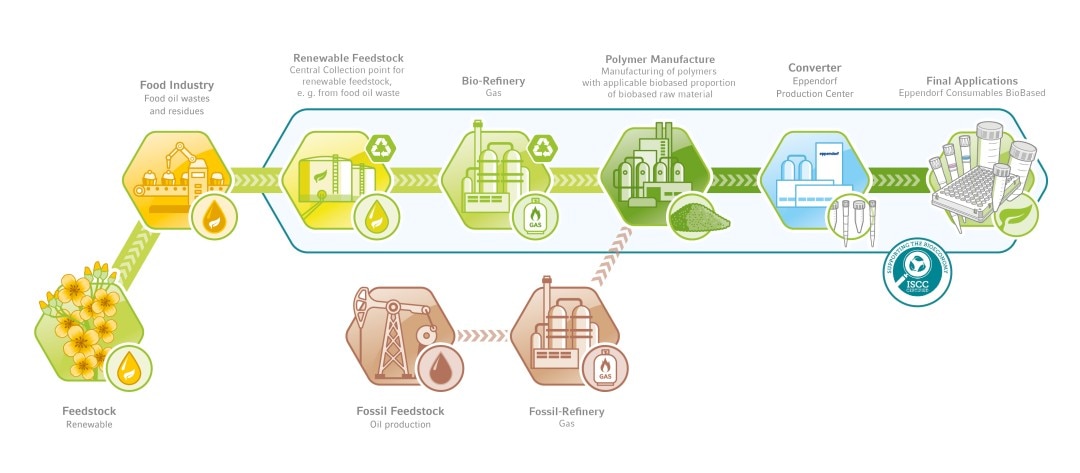

- Tubes*, tips and plates are made from renewable feedstock (recycled e.g. from food oil wastes and residues), applying ISCC mass balance approach. For details, see the product label.

- General Quality Certificates/Compliance with Standards are available separately for Eppendorf Tubes® BioBased, epT.I.P.S.® BioBased and twin.tec® PCR plates BioBased.

- Product-specific and lot-specific purity certificates, as well as an ISCC sustainability declaration for Eppendorf Tubes® BioBased, epT.I.P.S.® BioBased and twin.tec® PCR plates BioBased, are available to download from the product page.

* The screw caps are actual fossil-based material. The material switch will be made to BioBased in 2024.

Article: „Advancing Sustainable Science with Plastic Consumables made with Biobased Materials“

Neste and Eppendorf SE – two manufacturers of different products in separate industrial worlds – have joined forces to advance the topic of sustainability in the laboratory.

About Bio-based Polymers Used for Eppendorf Tubes® BioBased, epT.I.P.S.® BioBased and twin.tec® PCR plates BioBased.

- In the biobased polymer production, fossil raw material is replaced with sustainable raw material produced from renewable feedstock, preferably of 2nd generation, e. g. biobased waste and residues.

- We differentiate between one-component and multiple component consumables made of separate polymers: Polypropylene, Polyethylene, Polycarbonate

- Eppendorf Tips and the tubes vessels are made of 100 % biobased polypropylene.

- Unlike biobased Eppendorf Tips and Tubes, twin.tec PCR plates BioBased are primarily composed of two renewable polymers. The renewable material content is 100 % for the polypropylene wells and 77 % for the polycarbonate frame. Being weighted by the material’s respective mass, this results in an average renewable biobased content of 86 %.

- The renewable feedstocks used to produce the raw materials can be backtraced to the first collection points. The origin of the renewable raw materials from carefully selected suppliers committed to sustainability is assured.

- The final polymers are sustainability certified by »ISCC PLUS« – the leading global certification scheme for manufacturers of biobased polymers and downstream converters.

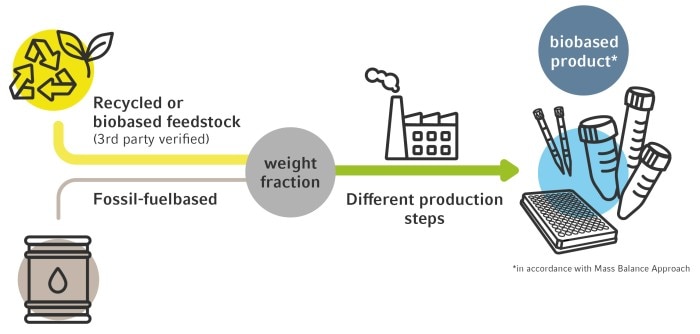

The mass balance approach – Certification of complex product chains in the circular economy

»How to measure the number of renewable fractions in a final product, when polypropylene or other plastic made from building blocks from bio-naphtha has the same properties as polymers made of crude oil?«

Renewable feedstock replaces an equivalent amount of virgin feedstock from crude oil at the beginning of the value chain. First step: the exact quantity of renewable feedstock (here the bio-naphtha) which is needed for the production of a certain product has to be determined. In a second step, it has to be determined what quantity of fossil-fuel-based feedstock can be replaced by renewable feedstock. The amount of replaced feedstock is then allocated to the product so that the input amount matches the output in tons.

White Paper: „Consumables Made of Bioplastics Enter the Lab“"

Can we solve the plastic problem? Plastic has entered our daily life. But as versatile and necessary as it is, it also has a major ecologic impact since it is made from fossil fuels. Bioplastics produced from plants like sugar cane seem to be an alternative, but this approach also has its drawbacks. Intending to build a circular economy, waste streams are coming into focus as a source for the production of plastics.

The path from vegetable cooking oil to Eppendorf Consumables BioBased

Read more

Read less

Downloads

Brochures & Flyers

Read more

Read less